Bunn CW Series Instruction Manual: A Comprehensive Guide

This manual details the Bunn CW Series – CT, CTF, CWT, CWTA, CWTB, and CWF models – offering comprehensive guidance for installation, operation, and maintenance․

Bunn-O-Matic’s commitment to reliable beverage equipment and support is reflected throughout this document, ensuring optimal performance and longevity․

The Bunn CW Series represents a significant advancement in cold water dispensing technology, offering both still and sparkling water solutions for commercial environments․ These brewers, including models CT, CTF, CWT, CWTA, CWTB, and the SINGLE CWF, are designed for reliability and ease of use, backed by Bunn-O-Matic’s long-standing reputation․

Founded on five generations of family entrepreneurship, Bunn delivers dependable beverage equipment and exceptional post-purchase support․ This manual provides a detailed overview of the series, covering installation, operational guidelines, maintenance procedures, and troubleshooting tips․

Whether you’re utilizing Portion Control (PC) or Push Button (PB) models, this guide will ensure optimal performance and customer satisfaction․ Bunn’s dedication to innovation is evident in features like Picture Prompted Cleaning systems and Digital Brewer Control․

Understanding Bunn-O-Matic Corporation

Bunn-O-Matic Corporation has a rich history spanning five generations of family entrepreneurship, establishing itself as a global leader in beverage equipment․ Headquartered in Springfield, Illinois, with a mailing address of Post Office Box 3227, Bunn is dedicated to providing reliable solutions and outstanding support to its customers worldwide․

The company’s commitment extends beyond manufacturing; Bunn prioritizes post-purchase assistance, ensuring long-term satisfaction․ Contact Technical Support at (800) 286-6070 for assistance․

Bunn’s innovative spirit is reflected in its diverse product line, including the CW Series, alongside offerings like the JDF-4S and ICB Twin Tall Platinum Edition․ Their dedication to quality and customer service makes them a trusted partner in the beverage industry․

CW Series Models Overview: CT, CTF, CWT, CWTA, CWTB, CWF

The Bunn CW Series encompasses a range of still and sparkling water dispensers designed for commercial use․ Models include the CT, CTF, CWT, CWTA, CWTB, and single CWF, each offering unique features to suit diverse needs․

CT models are available in both Push Button (PB) and Portion Control (PC) configurations, offering flexibility in dispensing options․ The CTF and CWT variants provide specific functionalities, while CWTA and CWTB cater to specialized applications․

These brewers require a cold water system operating between 20 and 90 psi, utilizing a 12-inch or larger supply line․ Bunn Refresh models, like the CT PC, are available in black or white finishes․

Installation and Setup

Proper installation is crucial for optimal performance․ Ensure a cold water connection with 20-90 psi pressure, utilizing a shut-off valve and regulator if needed․

Water Supply Requirements: Pressure and Line Size

The Bunn CW Series brewers necessitate a dependable cold water supply for consistent operation․ Specifically, these models – encompassing CT, CTF, CWT, CWTA, CWTB, and single CWF configurations – require operating water pressure to fall within the range of 20 to 90 psi (138 to 620 kPa)․

Furthermore, the supply line connecting to the brewer must be at least 1/2 inch (12mm) in diameter to ensure adequate water flow․ If your water system exceeds 90 psi, it is imperative to install a pressure regulator to reduce the pressure to a maximum of 50 psi (345 kPa)․

Failure to adhere to these specifications may compromise the brewer’s performance and potentially void the warranty․ Bunn-O-Matic strongly recommends professional installation to guarantee compliance with local plumbing codes and optimal functionality․

Installing a Shut-Off Valve

A dedicated shut-off valve is a crucial component of the Bunn CW Series installation, providing a convenient and essential means to isolate the brewer from the water supply․ This valve facilitates routine maintenance, repairs, and emergency situations without requiring a complete system shutdown․

The shut-off valve must be installed on the cold water line before the connection to the brewer․ Ensure the valve is readily accessible for easy operation․ A full-port ball valve is recommended for minimal flow restriction․

Proper installation prevents water damage and allows for safe servicing․ Bunn-O-Matic emphasizes the importance of a qualified plumber performing this installation to guarantee adherence to local plumbing regulations and a secure, leak-free connection․

Water Pressure Regulation (Above 90 psi)

Maintaining appropriate water pressure is vital for the optimal performance and longevity of your Bunn CW Series brewer․ If the incoming water pressure exceeds 90 psi (620 kPa), a pressure regulator must be installed on the supply line before the brewer connection․

Bunn-O-Matic recommends reducing the pressure to a maximum of 50 psi (345 kPa) using a suitable regulator․ Excessive pressure can damage internal components, leading to malfunctions and voiding the warranty․

Regularly inspect the regulator for proper function and ensure it’s correctly adjusted․ Proper regulation safeguards the brewer and ensures consistent beverage quality․

Connecting to the Cold Water System

Ensure the Bunn CW Series brewer is connected to a dedicated cold water supply line․ This line should be at least 1/2 inch (12mm) in diameter to provide adequate water flow․ Before connecting, verify the water supply is potable and meets local health regulations․

After installing the shut-off valve and, if necessary, the pressure regulator, carefully connect the water line to the brewer’s inlet fitting․ Hand-tighten the connection, then use a wrench to gently tighten another quarter turn․

Inspect for leaks immediately after connection and during initial operation․

Operational Guidelines

Bunn Refresh countertop models deliver still and sparkling water, with portion control (PC) or push-button (PB) operation for convenient dispensing of cold beverages․

Bunn Refresh Counter Top Models

Bunn Refresh counter top models represent a sleek and efficient solution for dispensing chilled, still, and sparkling water․ Available in both black and white finishes, these units cater to diverse aesthetic preferences․ The CT PC model offers precise portion control, ideal for environments requiring consistent beverage volumes, while the CT PB model provides simple, intuitive push-button operation․

These models, such as the 45800․0001 (Black PC) and 45800․0002 (White PB), are designed for ease of use and reliability․ They are built upon Bunn’s legacy of quality and backed by comprehensive support, ensuring a seamless beverage service experience․ The counter top design optimizes space utilization, making them suitable for various commercial settings․

Still and Sparkling Water Dispensing

Bunn CW Series brewers excel in delivering both still and sparkling water with consistent quality and temperature․ These systems connect directly to a cold water supply, ensuring a readily available source for refreshment․ The brewers are engineered to handle water pressures between 20 and 90 psi, requiring a shut-off valve for installation and a regulator if exceeding 90 psi․

Proper water pressure regulation is crucial for optimal performance and longevity of the unit․ The system’s design prioritizes efficient dispensing, minimizing waste and maximizing user convenience․ Bunn recommends adhering to specified water supply parameters for consistent results and to maintain the integrity of the sparkling water carbonation․

Portion Control Functionality (PC Models)

Bunn CW Series PC models offer precise portion control for consistent beverage dispensing, enhancing operational efficiency and reducing waste․ These models, like the BUNN refresh CT PC, allow operators to pre-program specific volumes of still or sparkling water․ This feature is ideal for environments requiring standardized serving sizes and cost management․

The digital brewer control features enable easy adjustment of portion sizes, catering to diverse customer preferences․ The PC functionality streamlines operations, minimizing manual adjustments and ensuring accurate dispensing every time․ This contributes to improved consistency and a superior customer experience, maximizing profitability․

Push Button Operation (PB Models)

Bunn CW Series PB models, such as the BUNN refresh CT PB, prioritize simplicity and ease of use with their intuitive push-button operation․ These models offer a straightforward dispensing experience, requiring minimal training for staff․ A single press delivers a pre-set volume of chilled still or sparkling water, making them perfect for high-volume environments․

The user-friendly design ensures quick and efficient service, enhancing customer satisfaction․ While lacking the programmable portion control of PC models, PB models provide reliable and consistent dispensing with a focus on operational simplicity․ This makes them a practical choice for locations prioritizing ease of use․

Maintenance and Cleaning

Regular cleaning and descaling are crucial for optimal performance and longevity of your Bunn CW Series brewer․ Utilize the Picture Prompted Cleaning Systems for guidance․

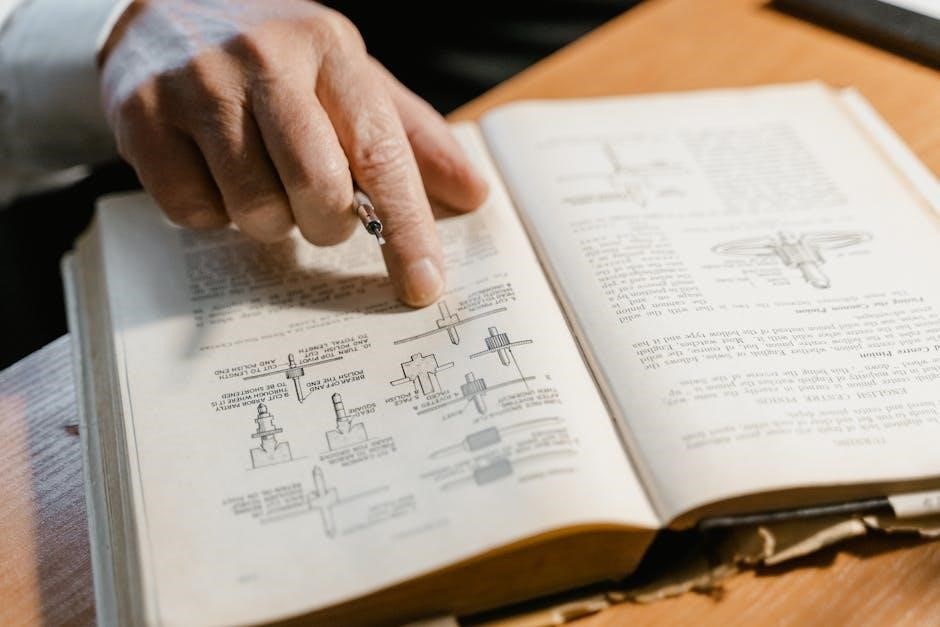

Picture Prompted Cleaning Systems

Bunn’s innovative Picture Prompted Cleaning Systems simplify the maintenance process, guiding users through each step with clear visual aids․ These systems ensure thorough cleaning and descaling, maximizing the lifespan and performance of your CW Series brewer․

The visual prompts eliminate guesswork, making it easy for staff to follow the recommended cleaning procedures consistently․ This feature is particularly beneficial for training purposes and maintaining hygiene standards․ Regular use of these systems prevents mineral buildup, ensuring optimal water flow and beverage quality․ Following the prompts diligently contributes to the longevity of the brewer and minimizes potential service calls․

Bunn prioritizes ease of use and efficiency, and the Picture Prompted Cleaning Systems are a testament to this commitment․

Regular Cleaning Schedule

Maintaining a consistent cleaning schedule is crucial for optimal performance and longevity of your Bunn CW Series brewer․ Daily cleaning should include wiping down exterior surfaces and flushing the dispensing nozzles․

Weekly, a more thorough cleaning of the drip tray and internal components is recommended․ Monthly descaling is essential to remove mineral buildup, especially in areas with hard water․ Utilize Bunn’s Picture Prompted Cleaning Systems for guided assistance․ Adhering to this schedule prevents blockages, ensures consistent water temperature, and preserves beverage quality․

Record cleaning dates to track maintenance and ensure adherence to the schedule, maximizing the brewer’s lifespan and minimizing potential issues․

Descaling Procedures

Regular descaling is vital for Bunn CW Series brewers, particularly in areas with hard water, to remove mineral buildup․ Begin by preparing a descaling solution according to the manufacturer’s instructions – Bunn recommends specific descaling solutions for optimal results․

Flush the solution through the brewer, following the Picture Prompted Cleaning System’s guidance․ Subsequently, thoroughly rinse the system with clean, cold water to eliminate any residual descaling agent․ Repeat the process if significant buildup was present․

Proper descaling ensures consistent water flow, temperature stability, and prevents damage to internal components, extending the brewer’s operational life․

Technical Specifications

Bunn CW Series brewers operate on 120V or 240V and feature digital brewer control․ They utilize a sophisticated heating system for optimal beverage temperature․

Electrical Requirements (120V/240V)

The Bunn CW Series brewers are available in both 120V and 240V configurations, necessitating careful attention to electrical compatibility during installation․ Verify your local power supply matches the brewer’s voltage requirement before connecting․

Improper voltage can cause significant damage to the unit and void the warranty․ Ensure a dedicated circuit is used, meeting the amperage demands specified on the brewer’s data plate․ Grounding is crucial for safety; always connect the brewer to a properly grounded electrical outlet․

Models like the ICB Twin Tall Platinum Edition operate on 120/240V, offering flexibility but demanding precise electrical setup․ Consult a qualified electrician if you are unsure about any aspect of the electrical connection․

Heating System Details

Bunn CW Series brewers utilize advanced heating systems designed for rapid and consistent temperature control, crucial for optimal beverage quality․ The “Soft Heat” technology, featured in models like the SH, ensures gentle heating, preserving flavor profiles․

These systems incorporate robust heating elements and precise thermostats to maintain water at the ideal dispensing temperature․ Regular descaling is vital to prevent mineral buildup, which can compromise heating efficiency and shorten the lifespan of the element․

The ICB Infusion Series employs a sophisticated heating process for superior coffee brewing, while the standard models offer reliable performance for various beverage applications․

Digital Brewer Control Features

Bunn CW Series brewers with digital controls offer enhanced programmability and monitoring capabilities․ These features streamline operation and ensure consistent beverage quality․ The Digital Brewer Control (DBC) allows for precise temperature adjustments and brewing parameters, optimizing flavor extraction․

Models equipped with DBC often include programmable timers and customizable dispensing volumes, catering to diverse user preferences․ The interface provides real-time feedback on system status, including water levels and heating cycles․

Furthermore, certain models support wired interfaces for seamless integration with compatible Bunn brewers, enabling centralized control and data logging․

Troubleshooting

This section provides solutions for common issues, including low water pressure and error codes, to ensure optimal Bunn CW Series performance and minimize downtime․

Common Issues and Solutions

Issue: Low Water Pressure․ Verify the water supply is fully on and within the required 20-90 psi range․ Check for kinks or obstructions in the water line․ If pressure exceeds 90 psi, a regulator is essential, reducing it to 50 psi to prevent damage․

Issue: Error Codes․ Consult the specific error code interpretation guide (detailed elsewhere in this manual) to diagnose the problem․ Codes indicate specific malfunctions, guiding repair efforts․

Issue: No Water Dispensing․ Ensure the shut-off valve is open․ Inspect the water inlet for blockages․ If issues persist, contact Bunn-O-Matic Technical Support for assistance․ Regular descaling prevents mineral buildup, a common cause of flow restriction․

Issue: Leaks․ Inspect all connections for tightness․ Address any leaks immediately to prevent water damage and maintain optimal operation․

Low Water Pressure Troubleshooting

Initial Check: Confirm the main water supply is fully open and that other fixtures aren’t simultaneously demanding high water flow․ Verify the brewer’s shut-off valve is completely open, allowing unrestricted water access․

Line Inspection: Carefully inspect the water line for any kinks, bends, or obstructions that could restrict water flow․ Ensure the line diameter is at least 1/2 inch for optimal pressure․

Pressure Verification: Use a pressure gauge to measure the incoming water pressure․ It must be between 20 and 90 psi․ If exceeding 90 psi, install a regulator to reduce it to 50 psi․

Inlet Filter: Check the water inlet filter for sediment buildup․ Clean or replace as needed to maintain unrestricted flow․

Error Code Interpretation

Diagnostic Alerts: The Bunn CW Series utilizes error codes to signal potential issues․ While specific codes vary by model (CT, CTF, CWT, etc․), consistent monitoring is crucial for swift resolution․

Common Codes: A “Low Water” code indicates insufficient water supply, requiring checks of the water line, shut-off valve, and inlet filter․ “High Temperature” suggests a heating system malfunction, necessitating professional service․

Troubleshooting Steps: Refer to the detailed error code list within the parts manual for precise diagnostics․ Attempt basic remedies like power cycling before contacting technical support․

Technical Support: For unresolved errors, contact Bunn-O-Matic Technical Support at (800) 286-6070․ Provide the error code and model number for efficient assistance․

Parts and Support

Bunn-O-Matic provides comprehensive support, including parts manuals, technical assistance at (800) 286-6070, and resources for models like the JDF-4S and ICB Twin Tall․

Contacting Bunn-O-Matic Technical Support

For dedicated assistance with your Bunn CW Series equipment, Bunn-O-Matic offers a robust technical support network․ You can reach their knowledgeable team by phone at (800) 286-6070․ This direct line connects you with specialists equipped to address a wide range of inquiries, from operational questions to troubleshooting complex issues․

Bunn-O-Matic prides itself on providing outstanding post-purchase support, ensuring customers receive prompt and effective solutions․ Beyond phone support, explore their website for frequently asked questions, detailed manuals, and potential online resources․ Don’t hesitate to leverage these tools to maximize your Bunn equipment’s performance and longevity․ Their commitment extends to five generations of family entrepreneurship, building trust and reliability․

Locating Parts Manuals

Accessing parts manuals for your Bunn CW Series brewer is straightforward, ensuring you can easily identify and order replacement components․ Begin by visiting the official Bunn-O-Matic website․ Utilize the search function, entering your specific model number – such as 45800․0001 for the CT PC Still and Sparkling model – to pinpoint the correct documentation․

These manuals provide detailed diagrams and part numbers, simplifying the repair and maintenance process․ Alternatively, contact Bunn-O-Matic’s technical support at (800) 286-6070 for assistance locating the appropriate manual․ Maintaining readily available parts information minimizes downtime and extends the life of your valuable Bunn equipment, upholding their legacy of reliability․

Bunn Commercial Series Details (JDF-4S, SH)

Beyond the CW Series, Bunn-O-Matic offers a robust portfolio of commercial brewing solutions․ The JDF-4S model is a 4-flavor cold beverage system featuring a 120V Silver Series with 4-segment LED graphics and portion control (37300․0080)․ For single brew applications, the SH model provides Soft Heat DBC technology in stainless steel, also at 120V, complete with funnel locks and a lower faucet (33600․0029)․

These systems demonstrate Bunn’s commitment to diverse beverage needs․ They are built with durability and efficiency in mind, mirroring the quality found within the CW Series․ Explore Bunn․com to discover the full range of commercial coffee and beverage equipment․

ICB Twin Tall Platinum Edition Specifications

The ICB Twin Tall Platinum Edition represents Bunn’s premium infusion series coffee brewer․ Operating at both 120/240V, this stainless steel unit (model 53400․0101) is designed for high-volume, consistent brewing․ It features a twin tall configuration, maximizing output capacity for demanding commercial environments․

This edition boasts advanced infusion technology, delivering exceptional coffee quality․ The Platinum Edition signifies a commitment to superior performance and durability․ It’s a testament to Bunn-O-Matic’s dedication to innovation within their broader product line, complementing the functionality of the CW Series with advanced brewing capabilities․

VPR Hopper Details (9lbs Capacity)

The Bunn VPR hopper is designed to seamlessly integrate with compatible Bunn brewers, offering a substantial 9lbs (4․1kg) capacity for holding coffee beans․ This larger capacity minimizes refill frequency, enhancing operational efficiency in busy environments․ It accommodates larger brew funnels, streamlining the brewing process․

An optional wired interface allows for communication between the hopper and compatible brewers, potentially automating bean delivery․ The VPR hopper is a commercial-grade component, built for durability and consistent performance․ It’s a valuable addition for establishments prioritizing quality and convenience alongside the CW Series․

Safety Precautions

Always follow general, electrical, and water safety guidelines when installing and operating the Bunn CW Series․ Prioritize safe practices to prevent hazards․

General Safety Guidelines

Before operating any Bunn CW Series brewer, thoroughly read and understand this instruction manual․ Ensure proper training for all personnel involved in installation, operation, and maintenance․ Always disconnect the brewer from the power supply before performing any servicing or cleaning procedures․

Never operate the unit with a damaged cord or plug, and avoid using extension cords․ Regularly inspect the water lines for leaks or damage, addressing any issues promptly․ Do not immerse the brewer in water or any other liquid․ Keep the surrounding area clean and free of obstructions to ensure adequate ventilation;

Bunn-O-Matic emphasizes responsible operation; improper use can lead to potential hazards․ Adhere to all local and national safety regulations․

Electrical Safety

Bunn CW Series brewers are available in 120V and 240V configurations; verify the correct voltage before connecting to the power supply․ Ensure the electrical outlet is properly grounded and meets all local electrical codes․ Never attempt to repair electrical components yourself – contact qualified Bunn-O-Matic technical support for assistance․

Avoid operating the brewer in damp or wet environments to prevent electrical shock․ Regularly inspect the power cord for damage, and replace it immediately if any issues are detected․ Do not use the brewer if the power cord is frayed or exposed․

Always disconnect the brewer from the power source before cleaning or performing maintenance․

Water Safety

The Bunn CW Series requires a cold water supply operating between 20 and 90 psi (138 to 620kPa) from a 12-inch or larger supply line․ Install a shut-off valve for easy maintenance and a regulator if pressure exceeds 90 psi, reducing it to 50 psi (345kPa)․

Use potable water only; do not connect to non-potable water sources․ Regularly inspect water lines for leaks and address them promptly․ Implement a descaling schedule to prevent mineral buildup, ensuring optimal water flow and brewer performance․

Bunn-O-Matic recommends following proper water filtration guidelines to maintain water quality and extend the life of the brewer․